Gas Line Repair and Installation Services

If you’re hesitant about tackling gas line repairs or installations, rest assured that with the right professional plumbing service support, you can handle these tasks safely and effectively. Understanding the intricacies of gas line systems and the importance of proper maintenance is just the beginning.

Curious about the common signs indicating potential gas line issues and the essential safety measures to take during repairs? Stay tuned to discover the crucial steps involved in detecting leaks and ensuring compliance with regulations for a seamless gas line installation or repair process.

Gas Line Service Essentials: Maintenance, Tools & Safety

- Conduct routine maintenance checks to proactively identify issues and ensure safe operation.

- Use proper tools like pipe cutters and wrenches for gas line installation.

- Obtain necessary permits, follow regulations, and consider system complexity for cost estimation.

- Detect gas leaks by visual inspection, gas leak detectors, and pressure tests.

- Professional inspection includes checking connections, fittings, grounding, and pressure testing.

Importance of Gas Line Maintenance

Regular maintenance of gas lines is crucial to ensure safe and efficient operation of your system. By conducting routine maintenance checks, you can proactively identify and address potential issues before they escalate into major problems. Inspecting the gas lines for leaks, corrosion, or damage is essential in preventing hazardous situations such as gas leaks or explosions. Proper maintenance also helps in maintaining the overall efficiency of your gas system, ensuring that it functions optimally and consumes energy efficiently.

During maintenance, it’s important to check for any signs of wear and tear on the gas lines, fittings, and connections. This includes inspecting for loose connections, rust accumulation, or any unusual noises coming from the system. Additionally, ensuring that the gas pressure is within the recommended range is vital for the safe operation of your gas appliances.

Regular maintenance not only enhances the safety of your gas system but also prolongs its lifespan, saving you from costly repairs or replacements in the future. By staying proactive with maintenance, you can enjoy peace of mind knowing that your gas system is operating safely and efficiently.

Common Signs of Gas Line Issues

Frequently overlooked signs of gas line issues can indicate potential safety hazards that require immediate attention. It’s crucial to be vigilant and address any warning signals promptly to prevent dangerous situations. Here are common signs that may indicate gas line problems:

| Signs of Gas Line Issues | Description |

|---|---|

| Rotten Egg Smell | Strong sulfur-like odor |

| Hissing Sounds | Unusual noises near gas lines |

| Dead Plants | Vegetation dying above buried gas lines |

| White Mist | Unexplained fog or mist near gas line |

| Higher Gas Bills | Sudden increase in gas expenses |

If you notice any of these signs, it’s vital to act swiftly. Ignoring these indicators can lead to gas leaks, fires, or explosions. Remember, safety should always be a top priority when dealing with gas line issues. If you suspect a problem, contact a professional gas line technician immediately to assess and address the issue before it escalates.

Safety Precautions for Gas Line Repair

When conducting gas line repair, prioritizing safety precautions is paramount to prevent potential hazards and ensure the job is completed safely and efficiently.

Before starting any repair work, it’s crucial to shut off the gas supply at the main valve to eliminate the risk of leaks or accidents.

Always wear personal protective equipment such as gloves and safety goggles to protect yourself from any potential gas leaks or injuries.

Prioritize working in well-ventilated areas to prevent the buildup of gas fumes, which can be harmful if inhaled.

Use a gas detector to check for any leaks before and after completing the repair to ensure the area is safe.

Avoid using any open flames or electrical devices near the repair site to minimize the risk of igniting gas leaks.

Lastly, always follow manufacturer instructions and local building codes when repairing gas lines to guarantee compliance and safety standards are met.

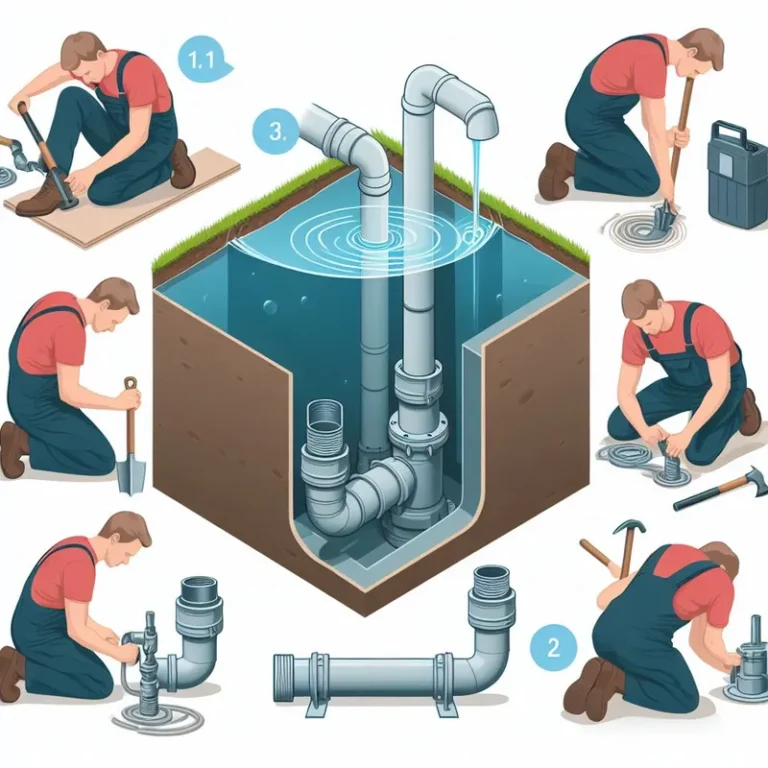

Tools Required for Gas Line Installation

To efficiently install gas lines, you’ll need specific tools designed for the task at hand. The essential tools for gas line installation include a pipe cutter, tubing cutter, pipe wrench, adjustable wrench, pipe reamer, deburring tool, gas leak detector, and a pressure gauge.

A pipe cutter is crucial for cutting the gas line to the required length accurately. A tubing cutter is used for cutting copper or plastic tubing without causing deformation. Pipe wrenches are essential for securing and turning pipes without causing damage. An adjustable wrench is handy for tightening and loosening fittings. A pipe reamer helps remove burrs and sharp edges from cut pipes, ensuring a secure fit.

Additionally, a deburring tool is necessary for cleaning the inside and outside of pipes before assembly. A gas leak detector is vital for ensuring there are no leaks once the installation is complete. Finally, a pressure gauge is used to test the system for any pressure drops, indicating potential leaks. Having these tools on hand will help you complete a gas line installation efficiently and safely.

Steps for Detecting Gas Leaks

For a thorough gas line installation project, ensuring the absence of leaks is critical. Detecting gas leaks requires precision and attention to detail. Start by conducting a visual inspection of the gas line, checking for any signs of damage or corrosion.

Next, use a gas leak detector, such as a gas leak detection solution or a gas leak detector pen, to pinpoint any leaks along the line. Pay close attention to connections, valves, and fittings, as these are common areas for leaks to occur.

After using a gas leak detector, perform a pressure test to further confirm the integrity of the gas line. This involves pressurizing the line with gas and monitoring for any drops in pressure, which could indicate a leak.

Additionally, consider using a gas leak detection device that can detect even the smallest leaks that may not be visible to the naked eye.

Professional Gas Line Inspection Process

Begin your gas line inspection process by thoroughly examining all connection points and fittings for any signs of wear, corrosion, or potential leaks. Check for loose connections, rust, or visible damage. Utilize a gas leak detector solution to identify any leaks that may not be immediately visible. Next, inspect the gas line for any bends, kinks, or physical damage that could compromise its integrity. Ensure that the gas line is properly supported and free from any obstructions.

Proceed to inspect the gas line for proper grounding to prevent potential safety hazards. Verify that the line is adequately bonded to prevent electrical issues. Additionally, check the gas line for proper labeling and identification to ensure compliance with safety standards.

Conduct a pressure test to assess the integrity of the gas line and identify any leaks under pressure. Finally, document your inspection findings thoroughly and address any issues promptly to maintain the safety and efficiency of the gas line system.

Permits and Regulations for Gas Line Work

Inspecting gas lines requires meticulous attention to detail and adherence to specific permits and regulations set forth by governing bodies to ensure safety and compliance. Before commencing any gas line work, it is crucial to obtain the necessary permits from local authorities. These permits typically outline the scope of work, required safety measures, and inspection protocols to be followed during the installation or repair process. Failure to comply with these regulations can result in serious consequences, including fines, project delays, or even legal action.

To give you a better understanding, here is a table summarizing some common permits and regulations related to gas line work:

| Permit/Regulation | Description |

|---|---|

| Building Permit | Required for the installation of new gas lines or major repairs |

| Gas Line Inspection | Ensures that the gas line installation meets safety standards |

| Zoning Regulations | Dictate where gas lines can be installed and any restrictions |

| Environmental Permits | Necessary if the gas line work may impact the surrounding environment |

Cost Factors in Gas Line Services

When considering the cost factors in gas line services, it’s essential to assess the specific requirements of the installation or repair project. Factors that influence the overall cost include the complexity of the system, the materials needed, labor expenses, and any additional permits or inspections required.

To better understand the cost breakdown, consider the following:

- System Complexity: The intricacy of the gas line system, including the number of appliances connected and the distance the line needs to span, will impact the overall cost.

- Materials Used: The type of piping material chosen, such as black iron, copper, or flexible CSST, will affect the project cost.

- Labor Expenses: Labor costs vary based on the scope of work, the expertise required, and the duration of the project.

- Permits and Inspections: Obtaining necessary permits and scheduling inspections can add to the total cost but are crucial for ensuring safety and compliance with regulations.

For professional gas line repair or installation service, call us today for a free quote and speedy service.

About Us

Kansas City Plumbers Today offer fast, reliable home services for plumbing installation or repair, HVAC and professional electrical services.

With extensive experience in handling common and complex issues or emergency service, our team saves you time and money, ensuring your home services are conducted with the utmost professionalism and efficiency.

DISCLAIMERThis site is designed to assist homeowners in connecting with local home service contractors. All home service contractors are independent and this site does not warrant or guarantee any work performed. It is the responsibility of the homeowner to verify that the hired home service contractor furnishes the necessary license and insurance required for the work being performed. All persons depicted in a photo or video may be actors or models and not contractors listed on this site.